1.

I want to tell you about Mike Rother’s book Toyota Kata, but we are going to have to take some turns to get there. You know how sometimes if you talk with someone who has been practicing a discipline or craft for a long time—and it almost doesn’t matter which one—they’ll tell you how, over time, it has shaped their life? It isn’t everyone that says this, which is maybe more interesting than that anyone says it, but some people will tell you (and maybe you’re one of those people) that their vocation, or their primary hobby, teaches them how to live. Rother’s book taught me that this also applies to industrial engineering and management practices.

I already had a hunch. It’s hard to explain why without getting into a long digression about manufacturing and the automobile industry in the US and Japan, but I will try to make it a short digression. Some really smart researchers have in effect devoted their professional lives to trying to answer questions something like: ‘why are Toyota manufacturing plants more productive and efficient than US plants?’ and ‘why can’t US companies seem to duplicate this success—even the ones who are specifically trying to employ the same manufacturing methods, and even though Toyota is very open in discussing, even publishing, these methods?’ This topic has been written about so much that an episode of This American Life is devoted to it.

If you’re skeptical about the dominance of Toyota in the 20th century, consider that from 1937 to 2008, it operated at a profit, gained market share, and produced more reliable cars than American automobile manufacturers. And Rother observes that US companies have been trying, openly, for decades, to mimic the Toyota Production System and failing to do so.

What Toyota eventually started calling the Toyota Production System is more or less what the process community in the US calls lean manufacturing, from the term lean production system, coined by John Krafcik in an article published in the MIT Sloan Management Review in 1988.

The process improvement community has a lot of lean true believers. When a company I worked at announced that a group of us would be taking Lean Six Sigma training, my favorite co-worker at the time, observing the reaction this received, commented to me, ‘I wish they’d calm down. It’s not a new religion.’ I wasn’t so sure.

Given the impact Japanese automotive manufacturing has had on the US economy, it’s not surprising that writers who think they’ve answered these question get excited. I wondered if I had picked up on some of that enthusiasm. I read books by J. Edwards Deming, Jeffrey Liker, John Shook, John Krafcik, and Jim Womack. A lot of it was dry, but there were always paragraphs that made my spine tingle in a way that would have made more sense if I were reading a book on another topic—a book by Pëma Chödrön on meditation, or even David Allen on time management, books whose authors purported to be telling you something that should have have a big impact on your life. But I wasn’t just picking up something in their tone. At times, reading Rother, I felt a strange disorientation, as if, lost in thought, I had wandered into another room and was now holding the wrong book.

And it wasn’t that these books were giving me insight into how to improve my career. I had by this time left the manufacturing industry. I was still doing technical writing and process improvement, but for office processes. I felt that these books were telling me how to live. This thought was a second layer of disorientation. Even after reflecting, and after going back and rereading a jarring paragraph, I found that I wasn’t mistaken. The text felt big. It felt bigger than my books on buddhism, on spirituality, on meditation. It felt fundamental, transcendent. It wasn’t until I read Jordan Peterson’s book Maps of Meaning that I started to see why.

It seems impossible it extricate or summarize the web of concepts of MoM. It is a huge book, and dense, and it doesn’t even cover that much ground. It circles and circles Jungian concepts and mythological examples, and it bores into them with explanations from modern psychology. It is utterly convincing. But if I were to pick one quote to summarize MoM, it would be from Jung.

“Until you make the unconscious conscious, it will direct your life and you will call it fate.”

Carl Jung

Consider this quote in the context that all of your perceptions are perceived first, and maybe only, by your unconscious mind. The feeling of being conscious of seeing something isn’t what is doing the seeing. If anything, it is the experience of several modules in our brain all firing their synapses in similar patterns, all looking at the same thing, creating this special feeling of consciousness.

The brain isn’t designed to observe objects. For millions of years, before our eyes even worked very well, we evolved to perceive threats and potential (typically reproductive or caloric) rewards. Our brain has grown a lot of sophisticated modules over the past few million years, but it hasn’t gotten rid of its underlying structures. The brain, at its base, still sees threats and potential rewards. And by sees, I mean sees. It sees them before, and with greater cognitive resonance than, our visual cortex. In the same way that you will pull your hand away from a hot object without a conscious thought, because the reaction is coming from your spinal column, not your brain, so your brain processes the contextual relevance of an object to your interests before you process it as an object with color and shape and so on. And mythology works at this level, the Unconscious level. So do rituals.

Myth is not primitive proto-science. It is a qualitatively different phenomenon. Science might be considered “description of the world with regards to those aspects that are consensually apprehensible” or “specification of the most effective mode of reaching an end (given a defined end).” Myth can be more accurately regarded as “description of the world as it signifies (for action).” The mythic universe is a place to act, not a place to perceive. Myth describes things in terms of their unique or shared affective valence, their value, their motivational significance. The Sky (An) and the Earth (Ki) of the Sumerians are not the sky and earth of modern man, therefore; they are the Great Father and Mother of all things (including the thing—En-lil, who is actually a process—that in some sense gave rise to them).

MoM, page 9.

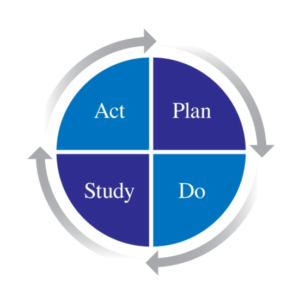

The reason myth acts in this way is because this is the way in which our brains most naturally act. We have evolved some cultural habits of observing objects as objects. But it’s a learned skill. Science, as the Pragmatists figured out, helps us understand the world the way works precisely because of these features of psychology. The scientific method is to make a prediction (to try to achieve an aim, even if, with our sophistication, we know we’re actually trying to disprove a hypothesis) and learn from the difference of what we expected and what resulted.

Science allows us to see because it puts reality in our way, makes it an obstacle, alters its significance by altering its context.

The reason the text of Rother’s book felt bigger was because my unconscious mind perceived its importance, before my conscious mind could.

The unconscious mind is always perceiving the world through its own language, and this affects the way we behave. And the less aware of this we are, the more we are subject to it.

2.

The reason that US corporations failed for so long at duplicating the success of Toyota, even as they were trying to duplicate their manufacturing techniques, is that these techniques are operating on at least three levels at once:

- They are natural and obvious patterns that emulate perfect flow. Whereas in buffered production systems, there are excesses of inputs and outputs upstream and downstream of each work station, so that if any work station runs into problems, the station after it has enough inputs to keep running for awhile, and the station before it has enough space to stack up outputs for awhile, lean production systems are modified to disallow this, so that if one work station encounters problems, those before it and after it have to stop, also. This weakness also has the advantage of being closer to the ideal of perfect flow than its buffered alternative. Imagine if work stations had no downtime, if there were no mechanical problems. Then you wouldn’t want buffer. You’d want each work station to deliver its output to the station downstream of it, which would make its improvements to the part, and hand it off, and so on. The the nirvana of industry. The TPS emulates that, moving always towards it.

- Because a lean production system is also fragile (meaning it has to stop for problems), if it is viewed correctly, it brings focus onto the problems of any production system. It alters the contextual significance of the problems in a facility, because those problems are stopping the line. They stop the line because management set up the production system so they would stop the line. This is is why many US companies gave up on a lean production system eventually. Without the perspective of seeing the system at its multiple levels of utility, the most obvious solution to a line stopping repeatedly is to add the buffer back, which is what happened, either all at once, in a throwing up of hands, or over time, as workers dealt with problems in the way most obvious to them. Without understanding that the point of a lean production system is to both show you your problems and force you to deal with them, if instead you are under the misperception that you should be able to set up your production system like Toyota’s and it will run smoothly, it’s hard come to any other conclusion than that lean just doesn’t work for your plant.

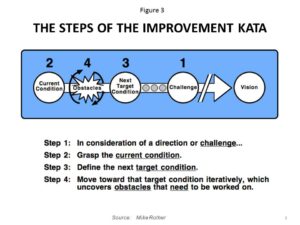

- Which brings us to the third layer: if you use your manufacturing facility like a laboratory, in which experiments in lean techniques result in clear reactions (lines stopping, failure to make daily production rates, and so on), and management is diligent and steadfast in its priorities, then there is plenty of incentive to be innovative in finding ways to solve the problems that are keeping you from your objectives, especially if the team works together to identify a Next Target Condition that, while challenging, is attainable. You don’t try to go from GM in the 1970’s to Toyota in the 1990’s in a single improvement. You set a series of what Rother calls “Next Target Conditions,” moving your process, inch by inch, closer to an ideal of one-piece-flow, in which waste and buffer are removed, and the process imperfections that keep you from achieving the Next Target Condition are diligently and scientifically dealt with, through a series of hypotheses and experiments, until eventually a breakthrough comes, and the Next Target Condition becomes the Current Condition, at which time the process starts over.

Seen this way, Toyota’s method was not, as US companies misunderstood for so long, precisely an engineering one. It was a ritualistic one. It operated at the psychological level, by 1. moving them towards an ideal, 2. showing them, among all the noise, what was their next obstacle to overcome, and 3. giving them the motivation to overcome it.

3.

In his book Maps of Meaning, Peterson describes these same concepts, but in different contexts. He explains how specific myths (from the Enûma Eliš to the Passion to the myth of St. George slaying the dragon) symbolically represent a hero voluntarily facing the threatening unknown, despite their fear, learning the nature of it, and overcoming it.

The alternative to voluntarily facing frightening and unknown threats is to avoid them. You might cultivate order and certainty in your established domain (your country, or city, or apartment, or brain) and try to ignore that changing reality around you. The problem with this technique is it is doomed 100% if the time if it runs long enough. Maybe some people can get through a lifetime living this way, but only because they are supported by society around them.

But do societies that are expansionist, that do not wall themselves in, that do not avoid threats, get to exist forever? I don’t know much history, but if I look at the US, it seems clear to me that, while we have a military and cultural presence throughout the world, we have a real education problem, which means a problem thinking. Too many of us are terrible at analysis and comprehension. And of course the symbolism of the myths applies to life in general, so a dragon can exist across the Atlantic, or it can exist in your medicine cabinet.

The US is super young by historical standards, and yet during our ascendant century, we have seen the beginning of mass extinction and the climatic prelude to much more mass extinction. Talk about a dragon. And what percentage of the population even think climate change poses a serious threat? According to a recent poll, 42%.

And a point that Rother and Peterson make is that development (improvement, growth, learning) doesn’t happen without struggle. Discomfort is a necessary part of change, and when the change is voluntary, this means the discomfort is partly from the willpower you are having to exert to make the change. The benefit is you can make the change before it is forced on you. Taiichi Ohno, in his book Toyota Production System: Beyond Large Scale Production (which I just finished reading this morning), also observes this. Ohno is the father of the Toyota Production System (though the Toyodas, Sakichi and Kiichiro, developed the Just-In-Time and self-stopping automation concepts) and, as he describes in his book, a tremendous amount of turmoil was involved in changing Toyota from a company that was trying to imitate Ford’s mass production, low-diversivity-product-blend system to what would become, first Toyota’s, and then Japan’s, iconic system of lower production, highly diverse product blend. This turmoil from Toyota staff came at a time when the head of the company was saying, we have to catch up with Ford in three years, or we’re done for. So it wasn’t that Ohno’s coworkers didn’t want change. The problem was they didn’t see his vision.

Which seems to be the situation the US is in today. It’s hard to find someone who doesn’t think we need to change what we’re doing. Disagreement seems to be around what’s wrong and what should we do differently.

So, I’ve posted three blogs now on this topic, and none of them are particularly good. Each of them comes close to getting at what I am trying to say, but none of them do it felicitously or all in the same essay.

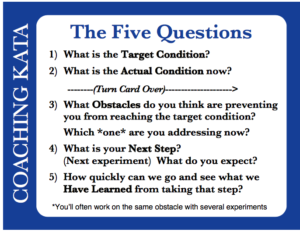

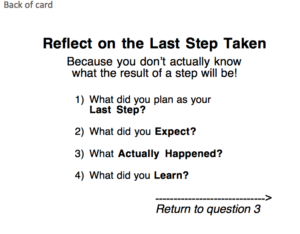

The Triumph of Fragility is wide-ranging, and goes into details on Peterson’s book. This essay talks more about my experience. John Dewey and Mike Rother: Pragmatic Dreamers focuses more how lean production techniques force workers to change, and describes Rother’s training material a little more.

None of these is very good. There are good reasons for that. One is that I still don’t understand them very well. And one reason for that is, for the past couple of years, I have been trying to blend time management techniques with Rother’s Improvement Kata. This has had some advantages. I have been relatively productive at work. I have not, however, learned very much about Rother’s IK. In November I will take training on the IK, and in the meantime, I am using his training material on its own, without blending with my existing practices. To fail to do this is a recipe for what Rother calls a “permanent beginner,” someone who never develops mastery at something because they haven’t drilled on the fundamentals of it.

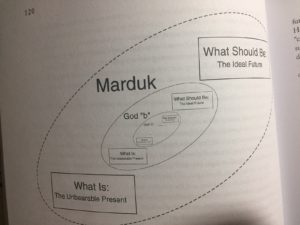

From Maps of Meaning, one of many illustrations of the ascent from the unbearable present towards an ideal vision of the future, iteratively.

From Maps of Meaning, one of many illustrations of the ascent from the unbearable present towards an ideal vision of the future, iteratively.  Rother’s Improvement Kata, his model that makes explicit what he inferred to be happening organically at Toyota.

Rother’s Improvement Kata, his model that makes explicit what he inferred to be happening organically at Toyota.